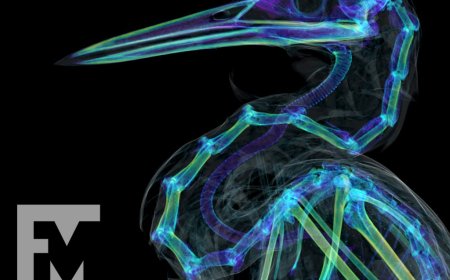

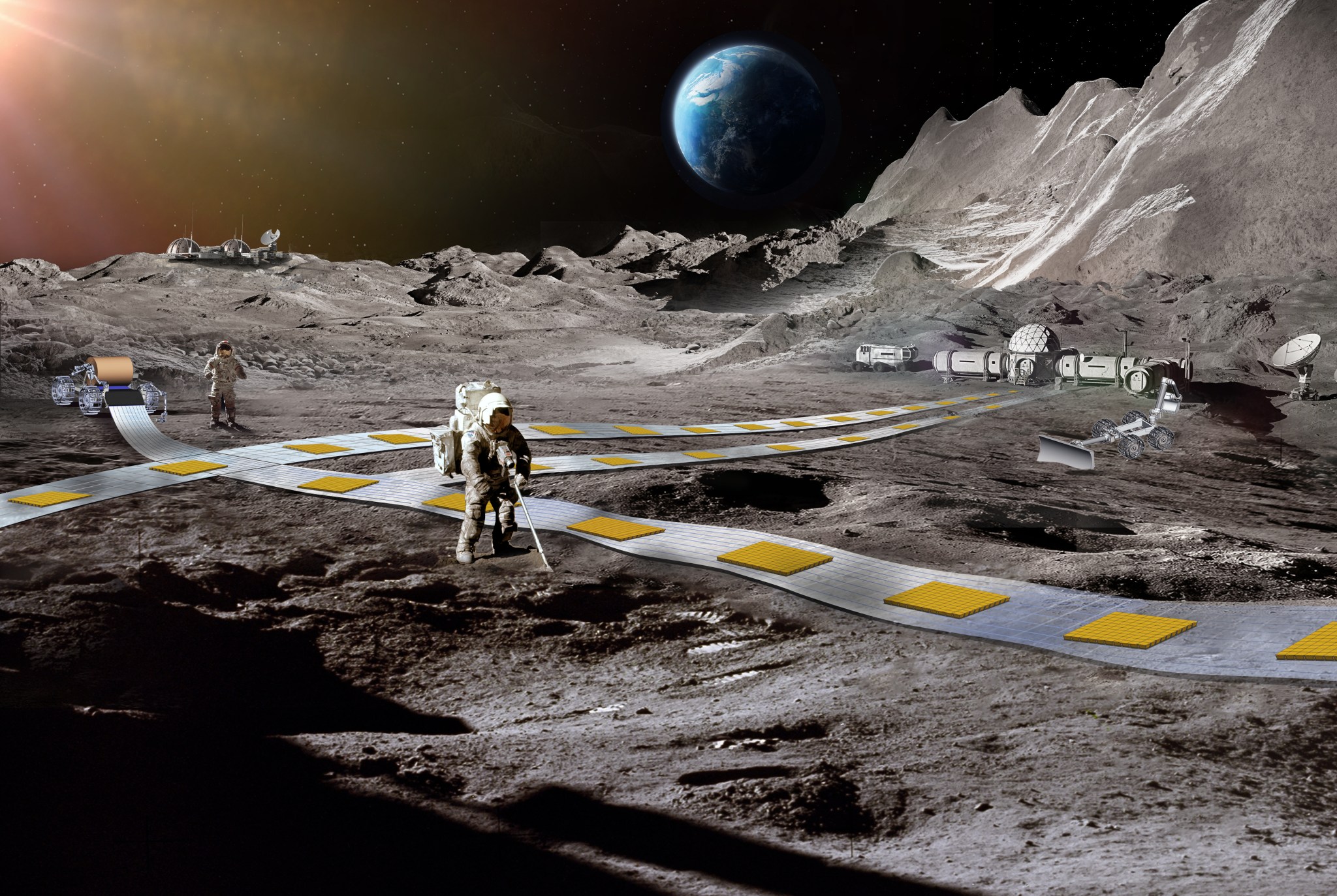

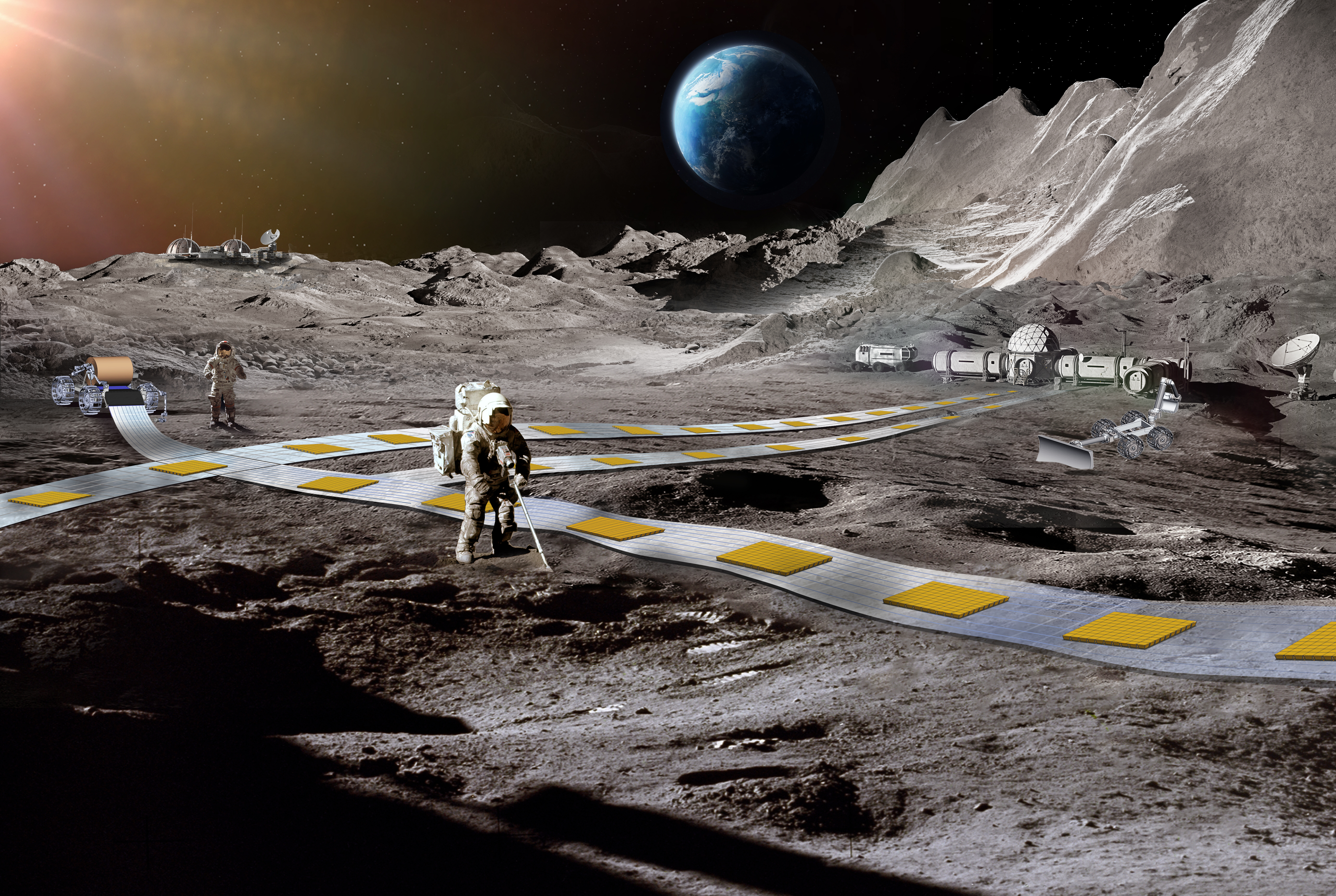

Flexible Levitation on a Track (FLOAT)

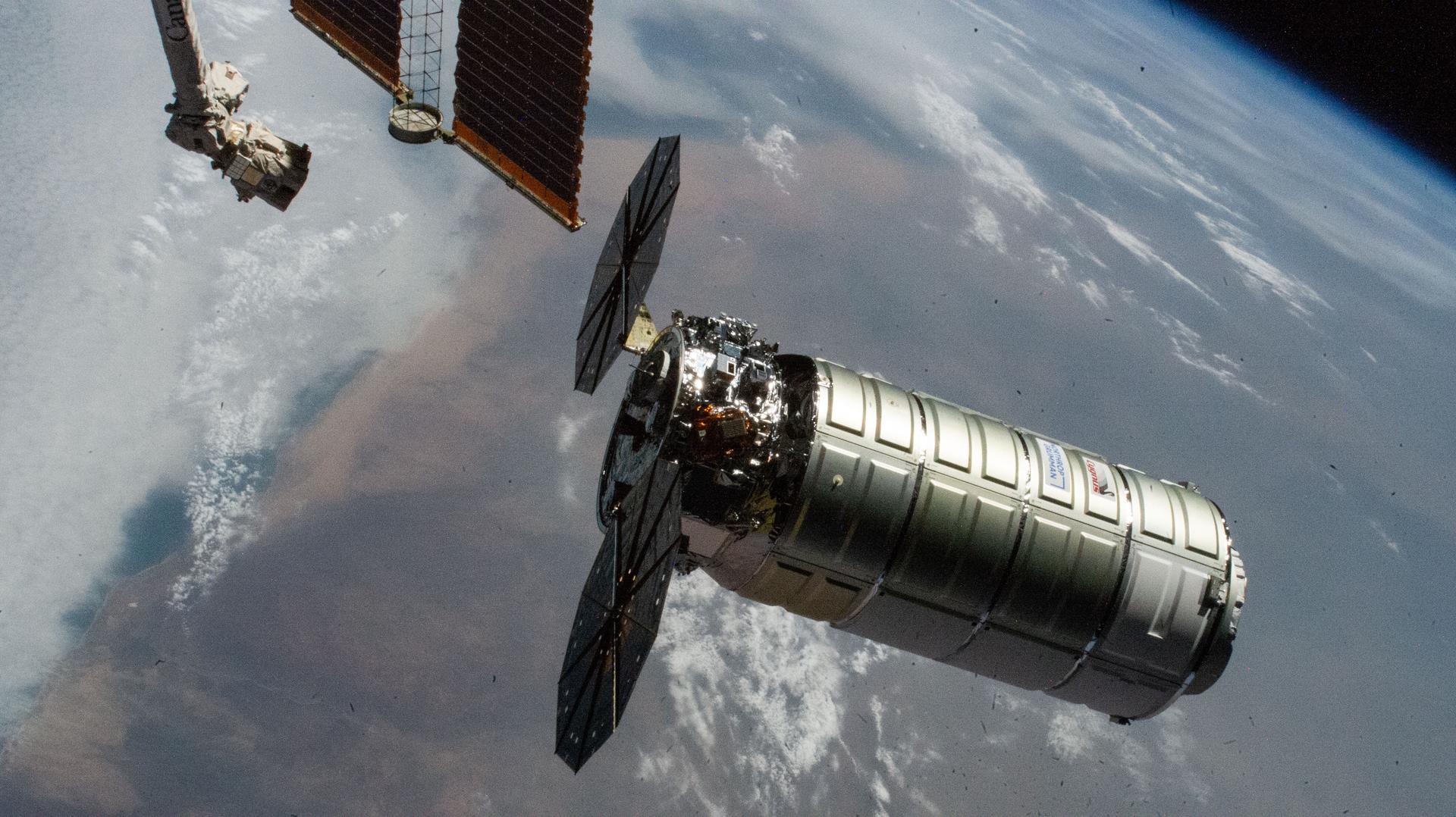

Ethan SchalerNASA Jet Propulsion Laboratory We want to build the first lunar railway system, which will provide reliable, autonomous, and efficient payload transport on the Moon. A durable, long-life robotic transport system will be critical to the daily operations of a sustainable lunar base in the 2030’s, as envisioned in NASA’s Moon to Mars plan […]

3 min read

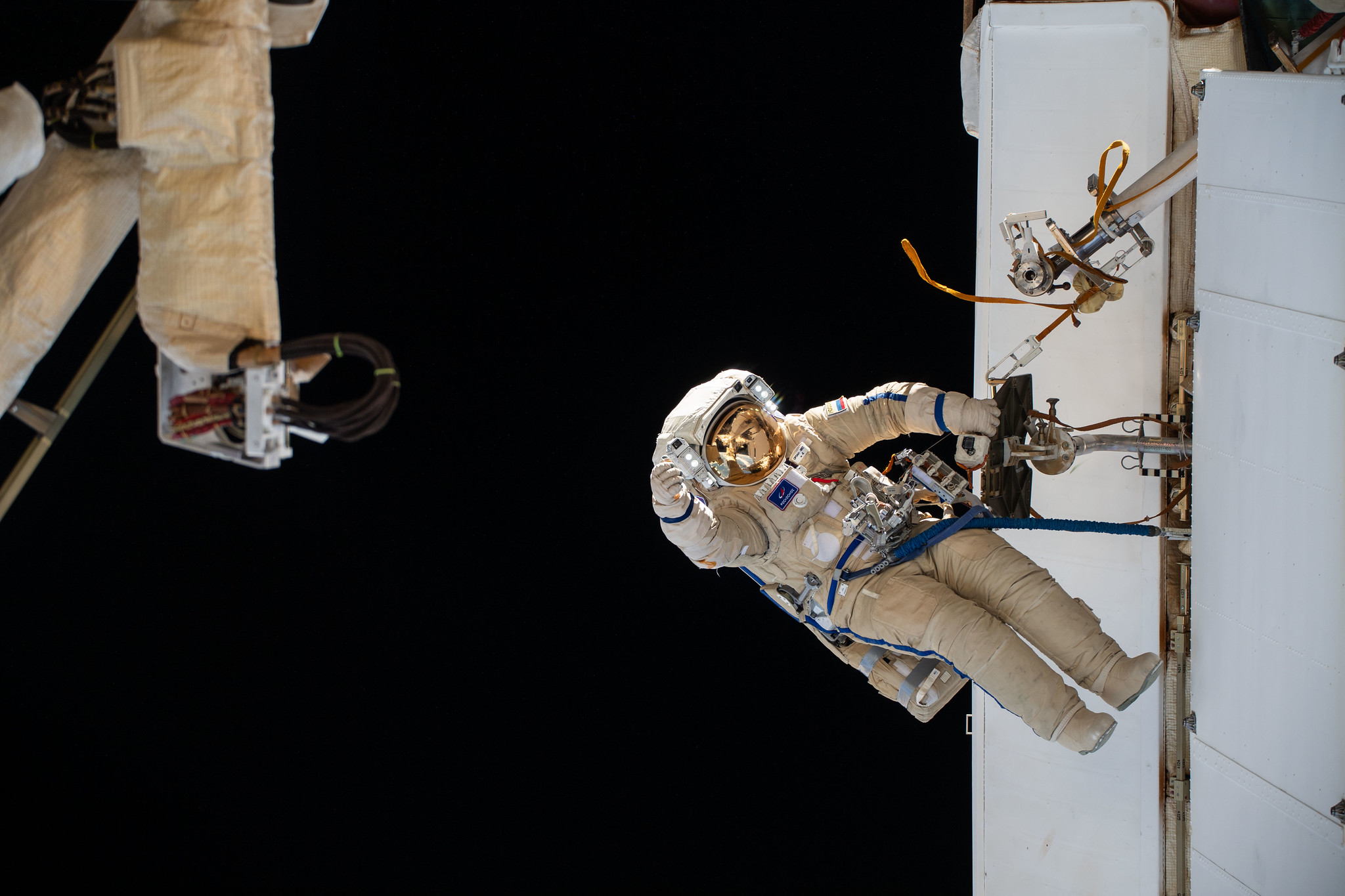

Preparations for Next Moonwalk Simulations Underway (and Underwater)

Ethan Schaler

NASA Jet Propulsion Laboratory

We want to build the first lunar railway system, which will provide reliable, autonomous, and efficient payload transport on the Moon. A durable, long-life robotic transport system will be critical to the daily operations of a sustainable lunar base in the 2030’s, as envisioned in NASA’s Moon to Mars plan and mission concepts like the Robotic Lunar Surface Operations 2 (RLSO2), to:

— Transport regolith mined for ISRU consumables (H2O, LOX, LH2) or construction

— Transport payloads around the lunar base and to / from landing zones or other outposts

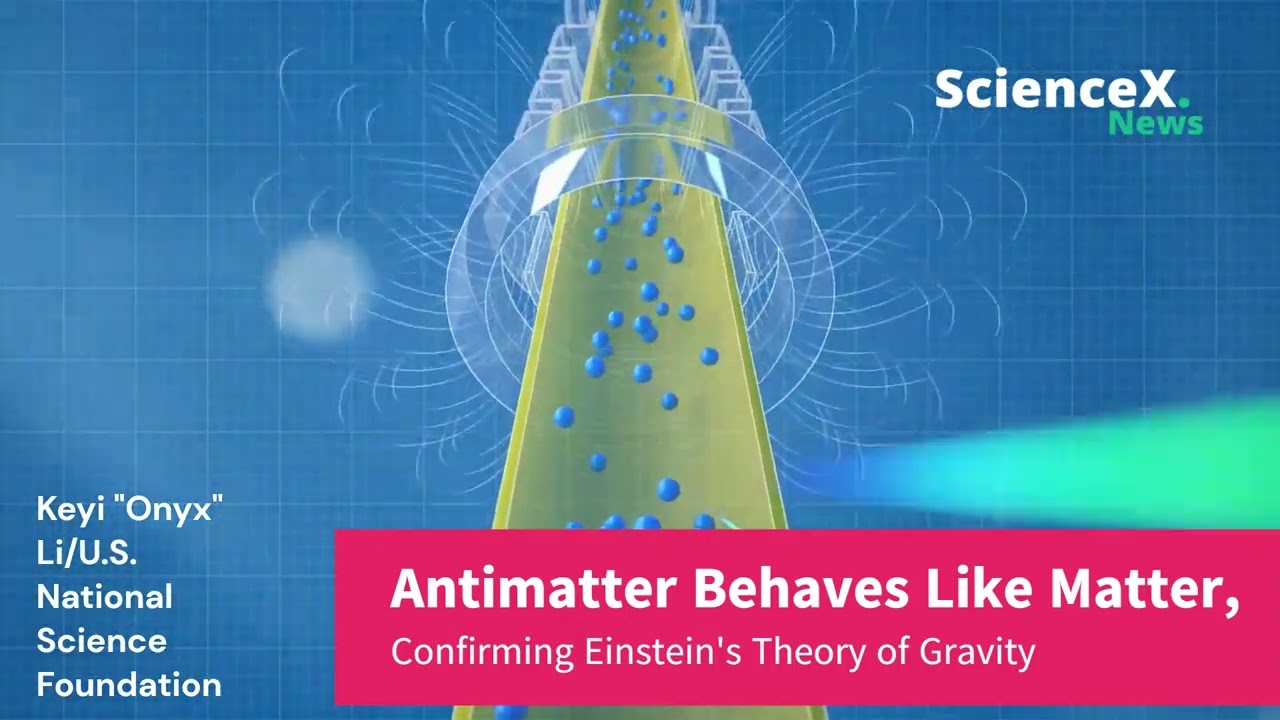

We propose developing FLOAT — Flexible Levitation on a Track — to meet these transportation needs.

The FLOAT system employs unpowered magnetic robots that levitate over a 3-layer flexible film track: a graphite layer enables robots to passively float over tracks using diamagnetic levitation, a flex-circuit layer generates electromagnetic thrust to controllably propel

robots along tracks, and an optional thin-film solar panel layer generates power for the base when in sunlight. FLOAT robots have no moving parts and levitate over the track to minimize lunar dust abrasion / wear, unlike lunar robots with wheels, legs, or tracks.

FLOAT tracks unroll directly onto the lunar regolith to avoid major on-site construction — unlike conventional roads, railways, or cableways. Individual FLOAT robots will be able to transport payloads of varying shape / size (>30 kg/m^2) at useful speeds (>0.5m/s), and a large-scale FLOAT system will be capable of moving up to 100,000s kg of regolith / payload multiple kilometers per day. FLOAT will operate autonomously in the dusty, inhospitable lunar environment with minimal site preparation, and its network of tracks can be rolled-up / reconfigured over time to match evolving lunar base mission requirements.

In Phase 2, we will continue to retire risks related to the manufacture, deployment, control, and long-term operation of meter-scale robots / km-scale tracks that support human exploration (HEO) activities on the Moon, by accomplishing the following key tasks:

— Design, manufacture, and test a series of sub-scale robot / track prototypes, culminating with a demonstration in a lunar-analog testbed (that includes testing various site preparation and track deployment strategies)

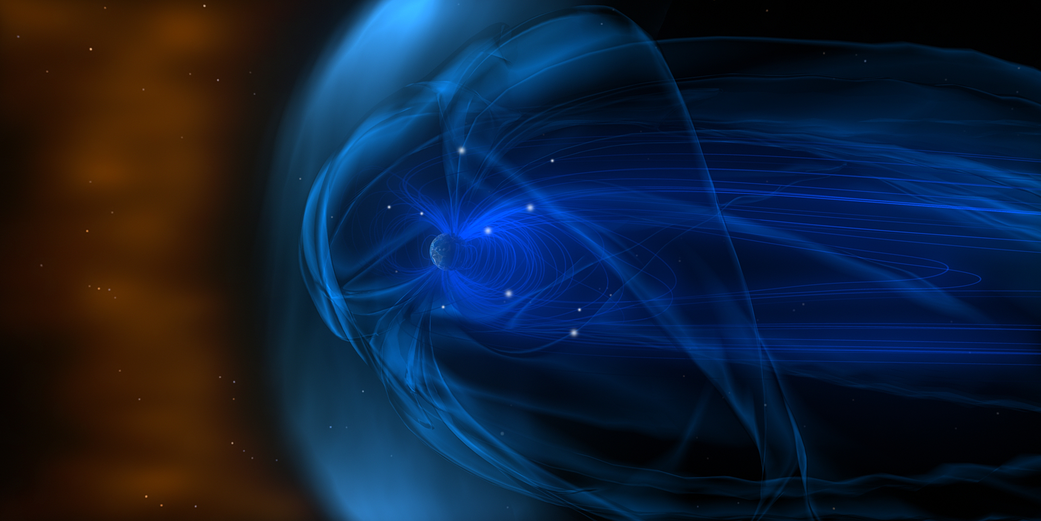

— Investigate impacts of environmental effects (e.g. temperature, radiation, charging, lunar regolith simulant contamination, etc.) on system performance and longevity

— Investigate / define a technology roadmap to address technology gaps and mature manufacturing capability for critical hardware (e.g. large-area magnetic arrays with mm-scale magnetic domains, and large-area flex-circuit boards)

— Continue refining simulations of FLOAT system designs with increased fidelity, to provide improved performance estimates under the RLSO2 mission concept We will also leverage these sub-scale prototypes to explore opportunities for follow-on technology demonstrations on sub-orbital flights (via Flight Opportunities / TechFlights) or lunar technology demos (via LSII / CLPS landers)

What's Your Reaction?