Mentoring the Next Generation of Engineers and Improving Shock Testing Standards

The year 2023 was productive for the Loads & Dynamics (L&D) Technical Discipline Team (TDT). New shock and modal analysis techniques were developed and mentoring the next generation of NASA discipline experts continued. Additionally, NESC Technical Bulletin No. 23-3, New Transient Finite Energy Shock Prediction Methodology, was released. Early Career Community Nurtures Development of NASA’s […]

The year 2023 was productive for the Loads & Dynamics (L&D) Technical Discipline Team (TDT). New shock and modal analysis techniques were developed and mentoring the next generation of NASA discipline experts continued. Additionally, NESC Technical Bulletin No. 23-3, New Transient Finite Energy Shock Prediction Methodology, was released.

Early Career Community Nurtures Development of NASA’s Future Discipline Leaders

NASA has acknowledged the need for “attracting and advancing a highly skilled, competent, and diverse workforce in order to cultivate an innovative work environment…” as stated in Objective 3.1 of the 2014 NASA Strategic Plan.

A survey conducted in 2014 by Emerge, the early-career professional group at JSC, showed that recent hires believe that “communication and collaboration amongst organizations” is a key area of improvement, while “lack of opportunities for professional growth” is the top reason why they would consider leaving the Agency. This, when coupled with NASA’s aging workforce (the average age as of 2016 was 49), stresses the importance of capturing knowledge to pass along to the next generation of NASA engineers.

The Structures, Loads and Dynamics, Mechanical Systems, and Materials (SLAMMS) disciplines have also been identified as critical fields for the advancement of NASA’s strategic vision, which emphasizes the importance of developing and retaining engineers in those areas. Consequently, the SLAM(M)S Steering Committee (Materials was not initially included), comprising center SLAMS Division/Branch Chiefs and NASA Technical Fellows, formed the Young Professionals Forum in 2012, which evolved into the current Early Career Forum (ECF) in 2017, and was expanded to provide year-round activities (e.g., monthly meetings, training opportunities) for the Early Career Community (ECC).

Over the lifetime of the ECC, the SLAMS Steering Committee was dissolved, and the stewardship of the ECC relied on the Technical Fellows, who empowered ECC leaders to take on the primary responsibility of planning and running the ECC and ECF events.

Today’s SLAMMS Early Career Community

Within the past few years, a new SLAMMS Division/Branch Chief collaboration group was formed, called the SLAMMS Leadership Working Group (LWG), and is led by James Loughlin, GSFC Mechanical Systems Division Chief, with co-lead Elonso Rayos, JSC Structures Engineering Assistant Division Chief. The LWG is a forum focused on capability sustainment, discipline technical challenges, and workforce concerns. For example, disparate Agency technical resource access is discussed, collaboration is coordinated, and critical gaps in expertise are filled using cross-Agency cooperation.

The current SLAMMS ECE leadership team includes Khadijah Shariff (JSC-Structures), Dr. Matthew Chamberlain (LaRC- Loads & Dynamics), Dr. Jonathan Sauder (JPL-Mechanical Systems), and Cassie Smith (JPL-Mechanical Systems). NASA Technical Fellows supporting SLAMMS are Deneen Taylor (Structures), Dr. Dexter Johnson (Loads & Dynamics), Dr. Michael Dube (Mechanical Systems), and Dr. Bryan McEnerney (Materials).

The SLAMMS Early Career Forum

The ECF is the annual “face-to-face” workshop for the community. The ECF is held at a different NASA center each year and features technical presentations by early career engineers (ECE), splinter sessions with NASA Technical Fellows, mentor presentations, facility tours, networking events, design challenges, and evening social activities to advance the SLAMMS disciplines and develop NASA’s future workforce. The ECF features technical presentations given by the ECEs to their peers, senior engineers, and Technical Fellows.

The 12th Annual SLAMMS ECF was held at MSFC and virtually. Sixty-six ECEs, Technical Fellows, TDT mentors, and discipline managers from the SLAMMS LWG were in attendance. ECEs from 8 centers made 16 technical presentations and 18 posters, which were ranked by mentors for the top awards. Multiple splinter sessions provided ECEs with opportunities to ask career-related advice from Technical Fellows, project and systems management, and individuals experienced in design, analysis, and testing. In addition, there was a detailed discussion for each of the technical disciplines represented at the forum, and multiple site tours were provided.

The Future of the SLAMMS ECC

The SLAMMS ECC will continue to evolve as discussions with the ECE leadership team and Technical Fellows continue towards mapping its future. SLAMMS is igniting cross-Agency collaboration for future generations. Its current goals include communication and collaboration among organizations, professional growth of early career engineers, knowledge capturing for the next generation of NASA engineers, and developing and retaining engineers in the specific SLAMMS disciplines. It will nurture the technical, professional, and personal development of NASA’s next generation of SLAMMS discipline leaders.

Updating Guidance on Shock Qualification and Acceptance Test Requirements

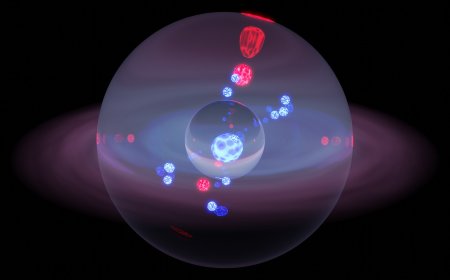

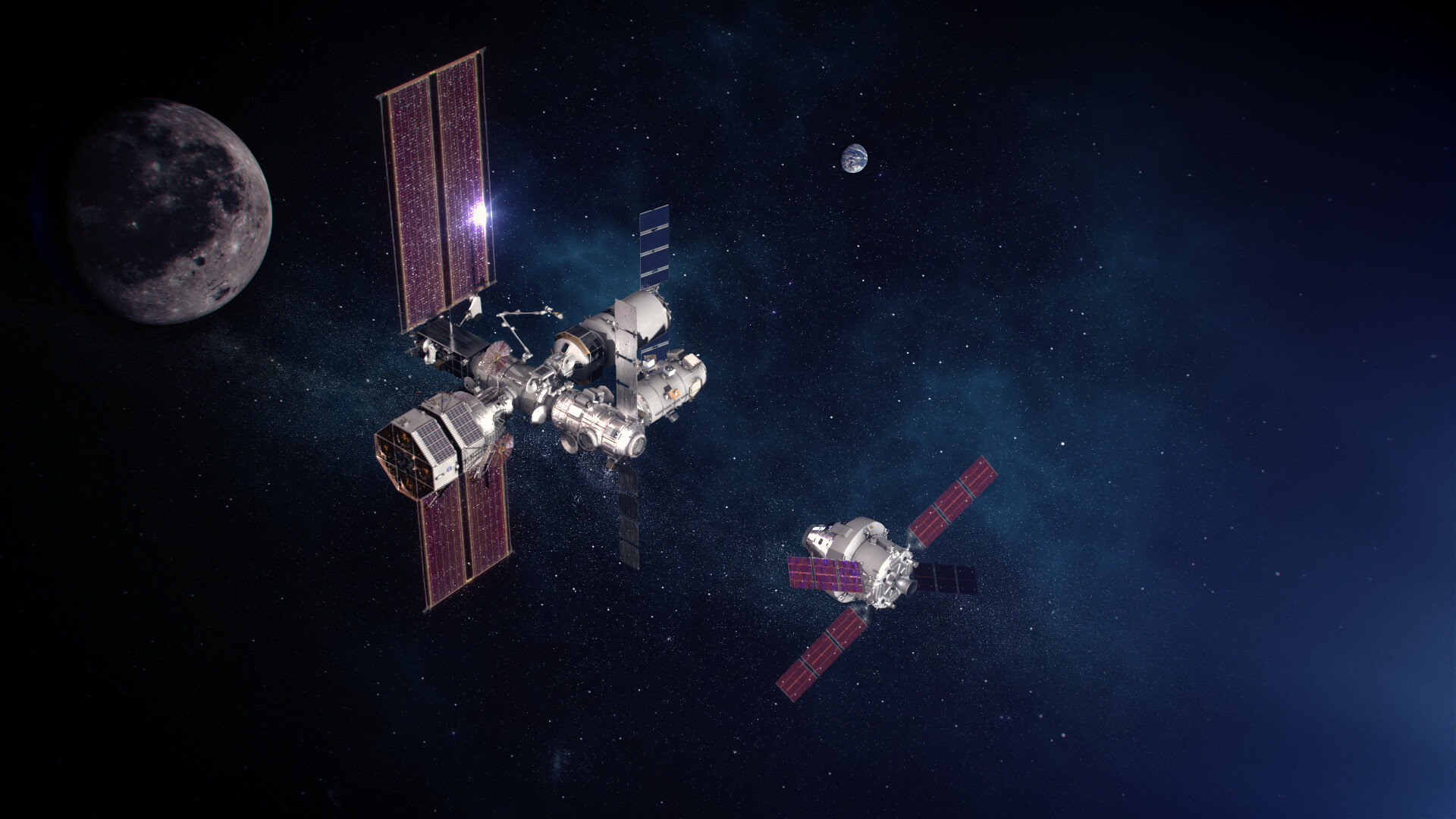

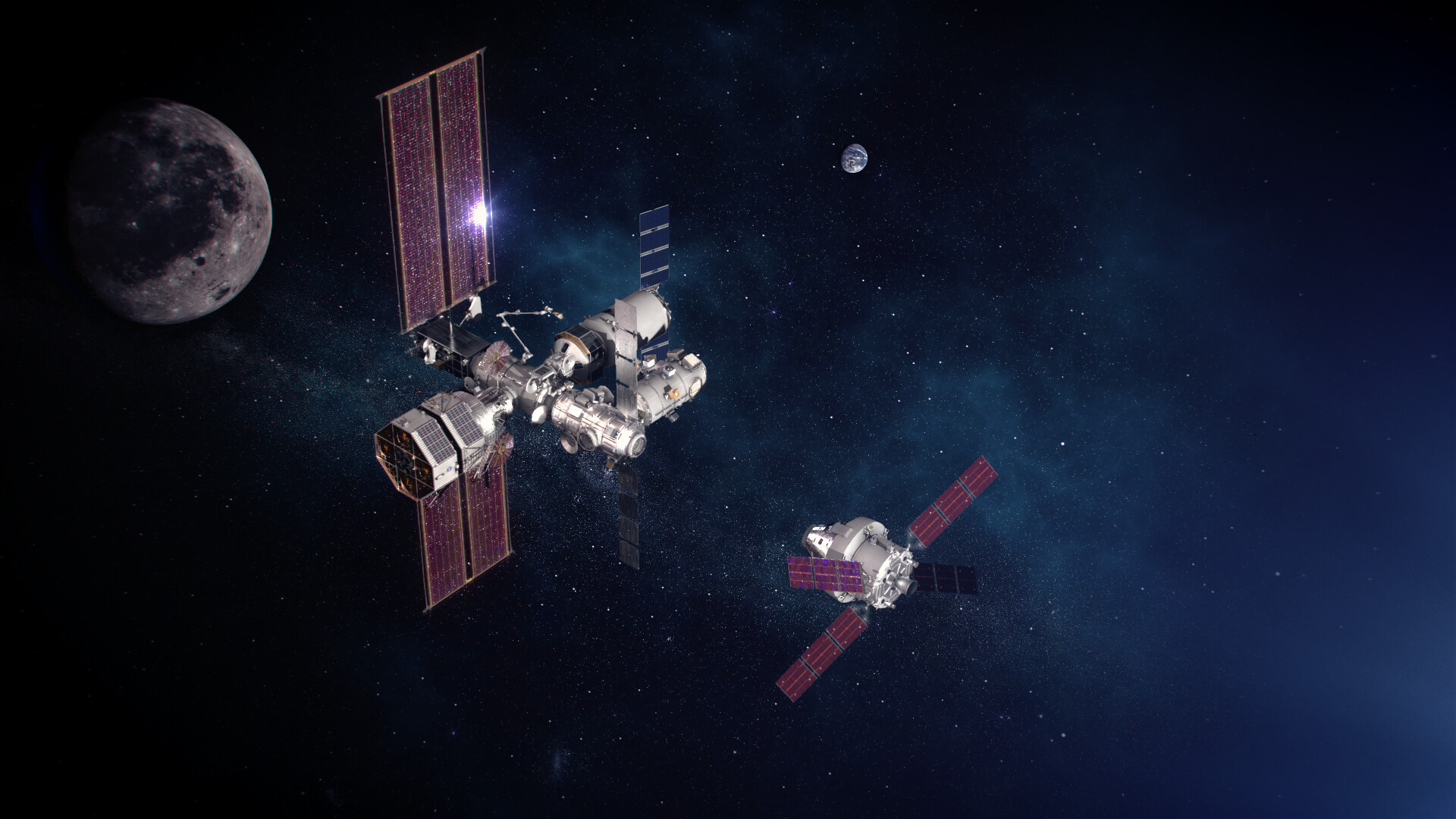

The L&D TDT has completed work that will have a positive impact on shock testing of NASA flight hardware. Pyroshock is the transient response of a structure to loading induced by activation of attached or incorporated pyrotechnic devices. Typical pyrotechnic devices include frangible bolts, separation nuts, and pin pullers that are used to assemble, separate, and reconfigure spaceflight hardware during a mission. Shocks can easily propagate through structure and damage sensitive components. Thus, successful pyroshock testing is considered essential to mission success. At the request of the Gateway Program Chief Engineer, the NASA Chief Engineer initiated an inquiry to reevaluate shock testing approaches for both unit and major assembly flight hardware and requested recommendations for potential revisions to NASA-STD-7003B, Pyroshock Test Criteria, that would clarify the guidance and applicability to new programs. The work delves into topics of shock acceptance and qualification testing for unit and major assemblies, shock test tolerances, shaker shock testing, and the distinction between mechanical shock and pyroshock testing. It also provides recommendations for their inclusion in the next Agency-wide revision of NASA-STD-7003B.

Current NASA-STD-7003B Requirements

Unit and major assembly flight hardware acceptance and qualification testing are discussed in NASA-STD-7003B. It requires that all units go through shock qualification testing, with few exceptions. The purpose of a qualification test is to verify the design integrity of the flight hardware. The standard calls for pyroshock qualification testing of nonflight hardware for externally induced environments to be performed with a 3 dB margin added to the maximum predicted environment (MPE), with two shocks per each orthogonal axis. Qualification tests are performed on hardware that will not be flown but is manufactured using the same drawings, materials, tooling, processes, inspection methods, and personnel competency as used for the flight hardware. The flight hardware is not recommended to go through shock test, therefore, it lacks workmanship screening testing. The required random vibration (RV) test is considered to be a partial workmanship screening, covering only up to 2000 Hz. A full workmanship screening test for unique and sensitive hardware that may have modes above 2000 Hz needs to be evaluated on a case-by-case basis by an expert in pyroshock dynamics and approved within a program’s risk management system and/or governing board.

The major assembly acceptance and qualification testing are not recommended, considering that the MPE and design margin cannot be demonstrated at the system-level tests. The major assembly unmargined testing, however, may achieve three objectives. First, the functional demonstration of shock separation devices—probably the most important part of the major assembly level testing—demonstrates the source electrical and mechanical hardware functions as expected, and the interface separates without any issues. Second, the major assembly testing provides the validation of the unit shock environments.

Third, the major assembly testing provides transfer functions (TF) that may help to estimate the attenuation—and in some cases structural amplifications—throughout the system with all assemblies in flight configuration. NASA-STD-7003B contains discussions for the first two major assembly test objectives. However, there are no discussions on the third test objective related to the TFs. The TFs provide qualitative assessment of shock propagation paths and attenuations at joints and interfaces. The TFs may be used qualitatively as attenuation is highly dependent on the materials and joint construction and may be different if there are changes in the system configuration.

Suggestions for Improving NASA-STD-7003B

The shock tolerance specified in NASA-STD-7003B is ±6 dB from 100 Hz to 3 kHz and +9/-6 dB above 3 kHz. The constant ±6 dB tolerance bandwidths across all frequencies are possible, as many existing shock simulation systems are able to simulate shock signatures that fall within these tolerances without difficulty. These tolerances are based on practical test implementation and shock simulation equipment consideration. The tolerance tightening should be considered at the flight hardware resonant frequencies to avoid over/under testing. However, if detonator or explosive shock simulation systems are used to qualify flight hardware, the shock tolerances above 3 kHz may be kept at +9/-6 dB.

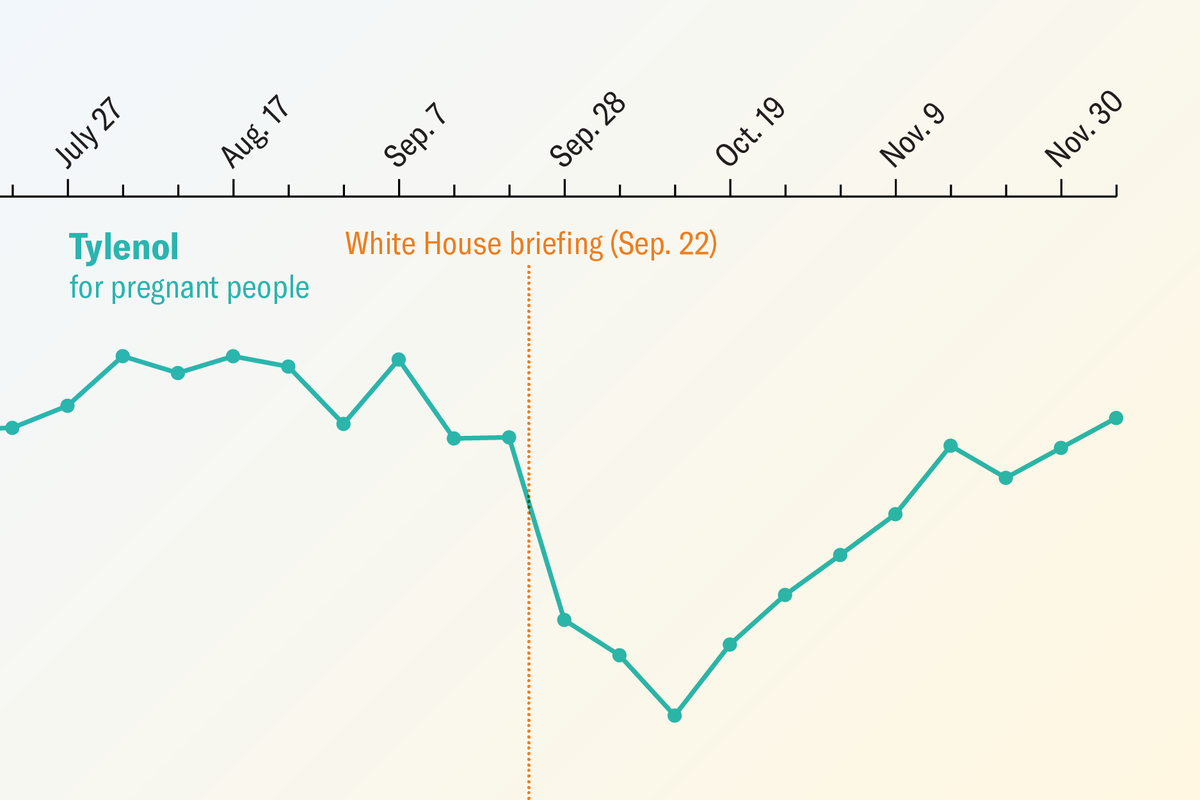

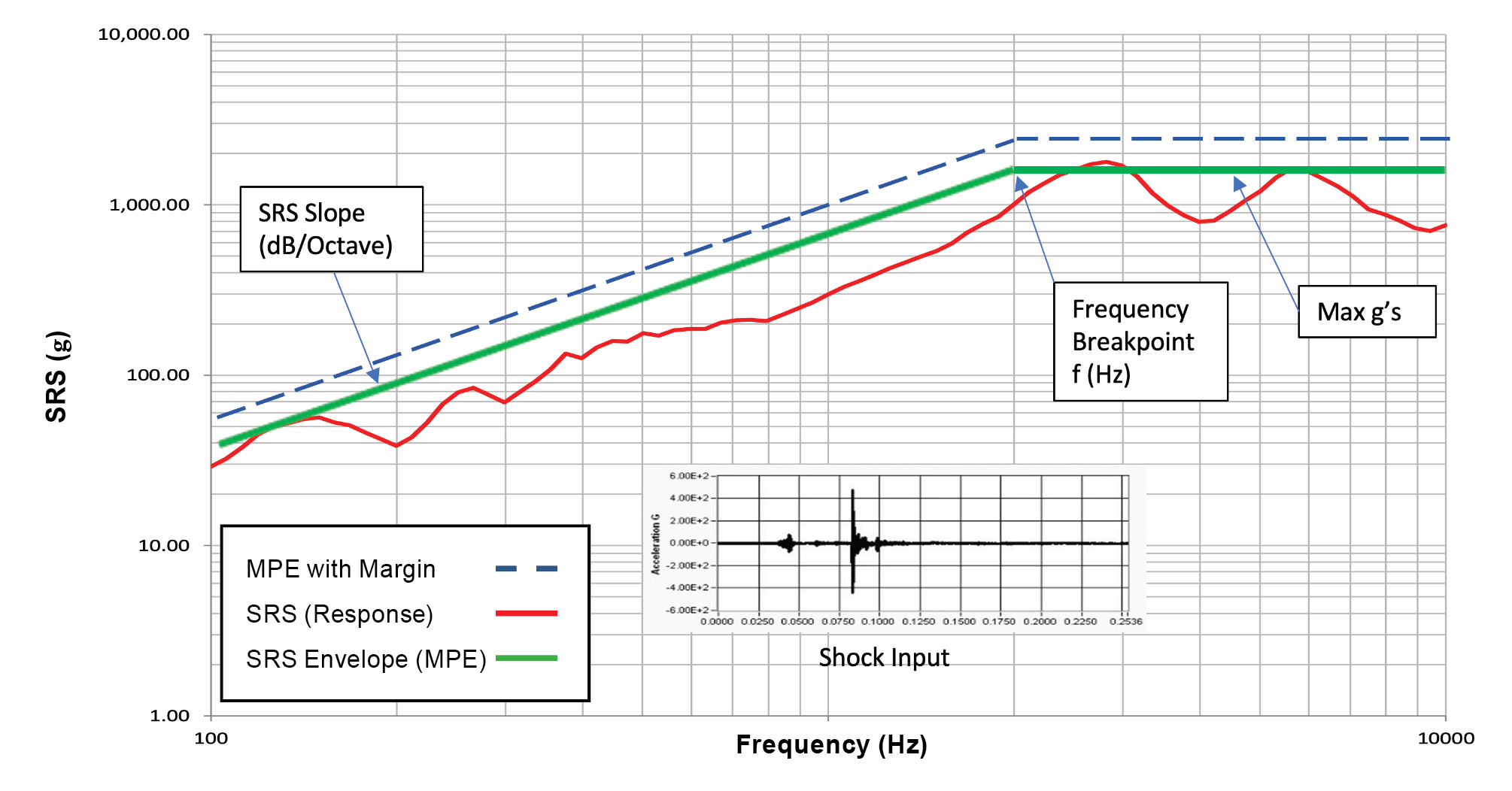

Measurements from many different pyro/non-pyro separation systems have been shown to have broader shock signatures and do not support the mechanical shock as being applicable to low- and mid-frequency shocks only. The standard discusses this topic and has an example of far field SRS indicating shock energy above 2 kHz. The future revision should clarify the applicability of the mechanical shocks to be broader and not to be limited to 2 kHz and below (see figure below).

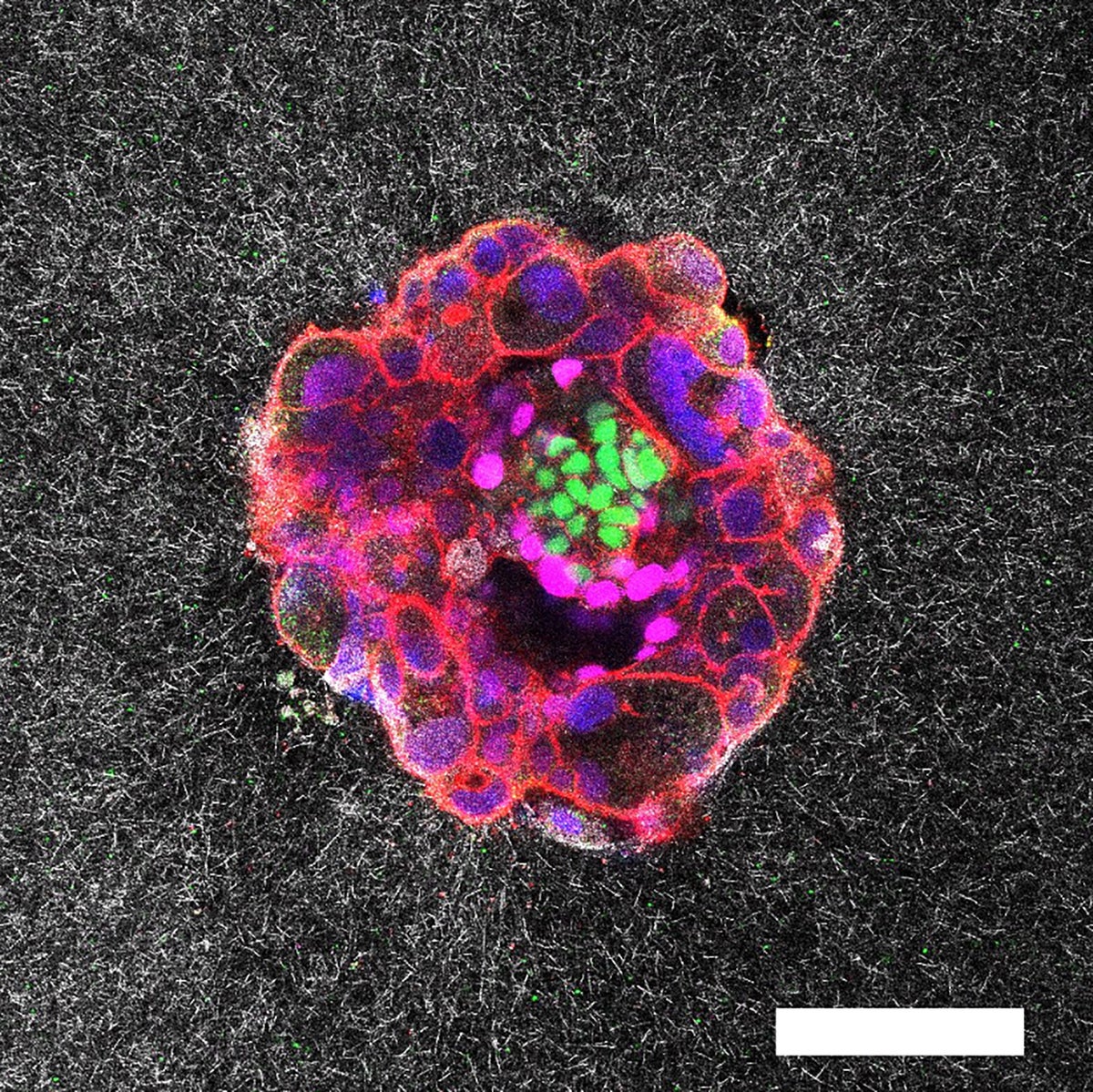

An example shock response spectrum (SRS) obtained from a mechanical shock separation system, indicating a broad signature is produced by pyro devices.

Even though shaker shock testing has been used in the past and is still used by some NASA organizations and contractors, there are multiple technical issues with this type of testing. The shaker-generated shock signatures in the low- and mid-frequency range (typically up to ~2 kHz) provide severe shock environments that may lead to structural failures. Most shakers are also not able to generate SRS above ~2 kHz, therefore, shaker shock test is deficient in meeting the shock requirement up to 10 kHz frequency. NASA-STD-7003B does not recommend the shaker method of shock testing due to the above limitations. This should be emphasized more in the standard. The shaker shock simulation test may be used if it is able to generate time histories that resemble signatures generated by space separation devices, and SRS levels meet the entire frequency range requirements.

For the next NASA-STD-7003B revision, recommendations are being made to include acceptance RV testing for partial workmanship screening testing, add the TFs to be used as qualitative information in assessing the attenuation in the structural shock paths, change the shock tolerance to ±6 dB across all frequencies, and consider mechanical shocks to be broader and not limited to low- and mid-frequency SRSs.

In summary, the updated guidance provides clarification to the question/uncertainty of the applicability of historical guidance to current programs, while ensuring proper applicability to future programs. This work directly benefitted the Gateway Program, and could potentially benefit the Human Lander System (HLS).

References:

- Kolaini, A.R., Kinney, T., and Johnson, D.: Guidance on Shock Qualification and Acceptance Test Requirements. SCLV, June 27-29, 2023, EL Segundo, CA. Available from: https://ntrs.nasa.gov/citations/20230009008

- NASA-STD-7003B, “Pyroshock Test Criteria,” June 11, 2020.

What's Your Reaction?