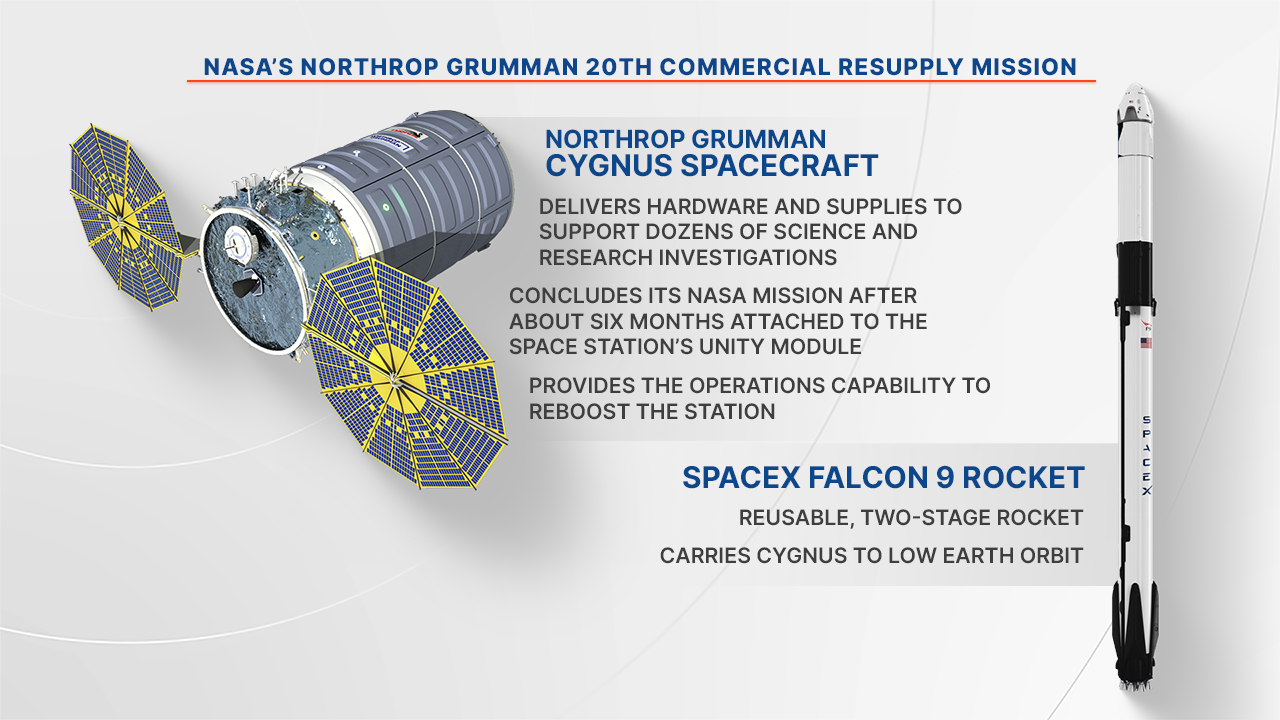

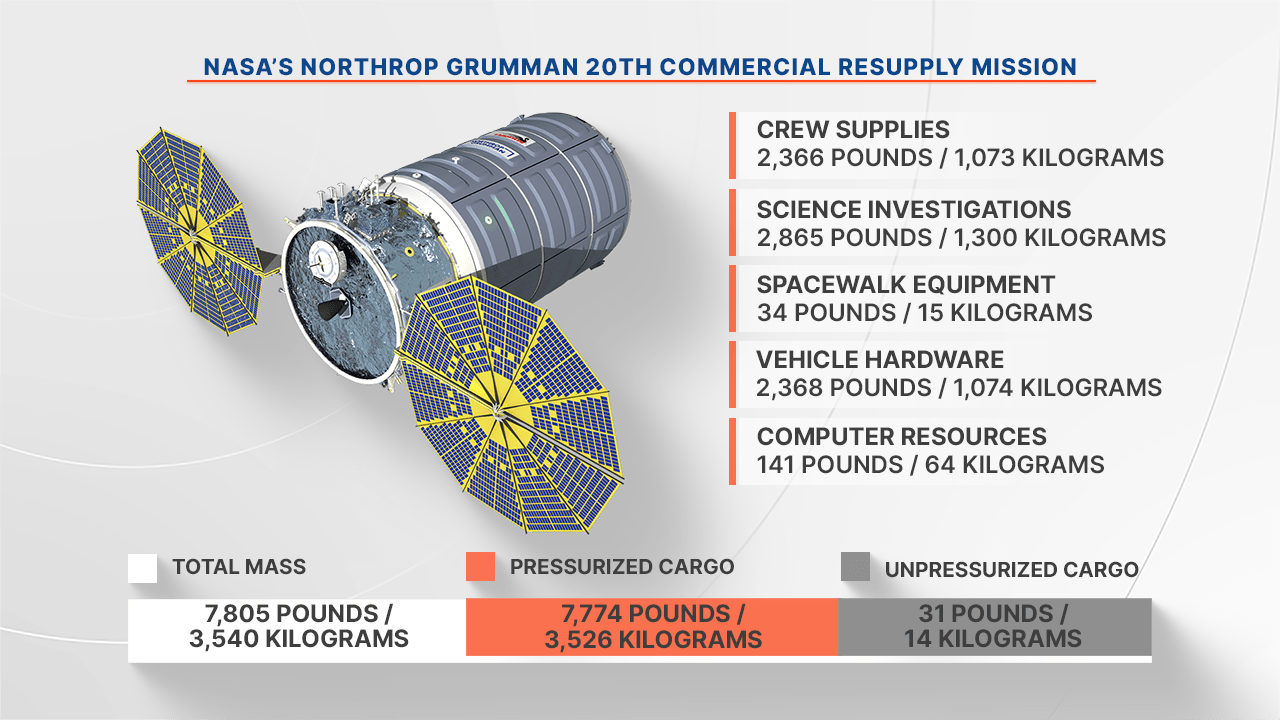

Overview for NASA’s Northrop Grumman 20th Commercial Resupply Mission

NASA, Northrop Grumman, and SpaceX are targeting 12:29 p.m. EST on Monday, Jan. 29, for the next launch to deliver science investigations, supplies, and equipment to the International Space Station. Filled with more than 7,800 pounds of supplies, the Cygnus cargo spacecraft, carried atop the SpaceX Falcon 9 rocket, will launch from Space Launch Complex […]

NASA, Northrop Grumman, and SpaceX are targeting 12:29 p.m. EST on Monday, Jan. 29, for the next launch to deliver science investigations, supplies, and equipment to the International Space Station. Filled with more than 7,800 pounds of supplies, the Cygnus cargo spacecraft, carried atop the SpaceX Falcon 9 rocket, will launch from Space Launch Complex 40 at Cape Canaveral Space Force Station in Florida. This launch is the 20th Northrop Grumman commercial resupply services mission to the orbital laboratory for the agency. The backup launch opportunity will be at 12:07 p.m. Tuesday, Jan. 30.

Live launch coverage will begin at 12:15 p.m. and air on NASA+, NASA Television, the NASA app, YouTube, and on the agency’s website, with prelaunch events starting Wednesday, Jan. 24. Learn how to stream NASA TV through a variety of platforms

Learn more at: nasa.gov/northropgrumman

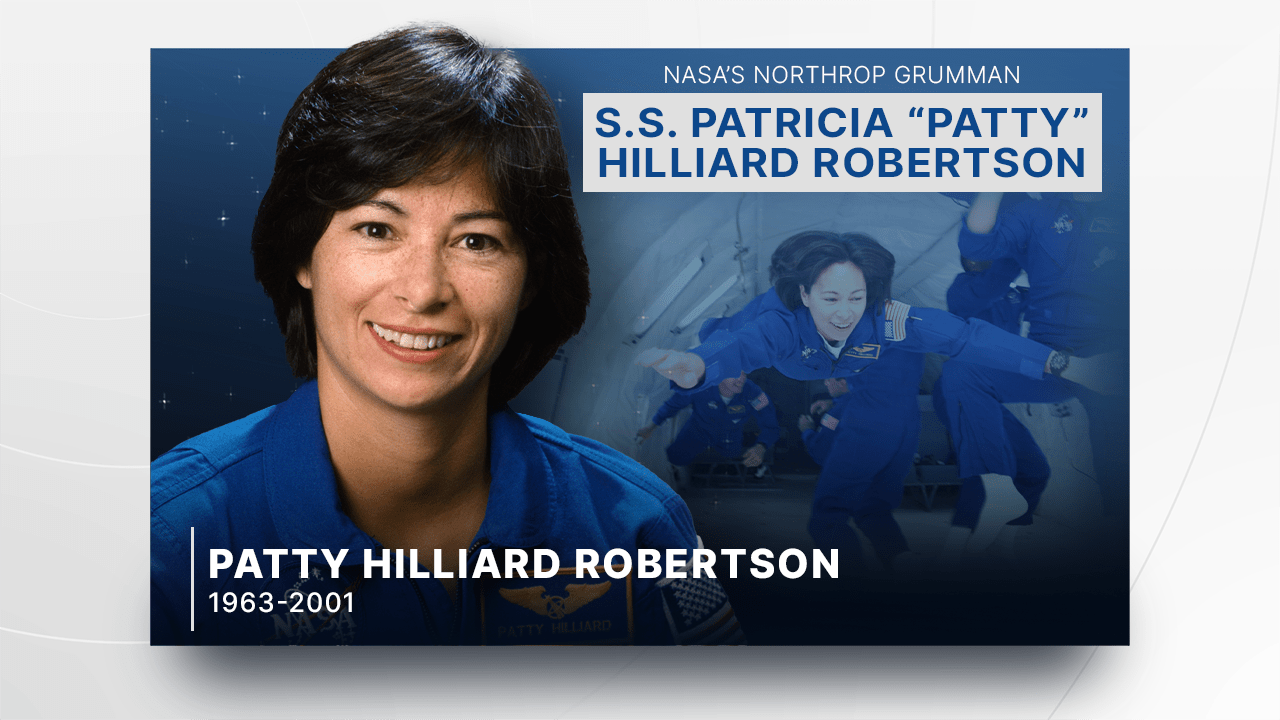

Northrop Grumman S.S. Patricia “Patty” Hilliard Robertson

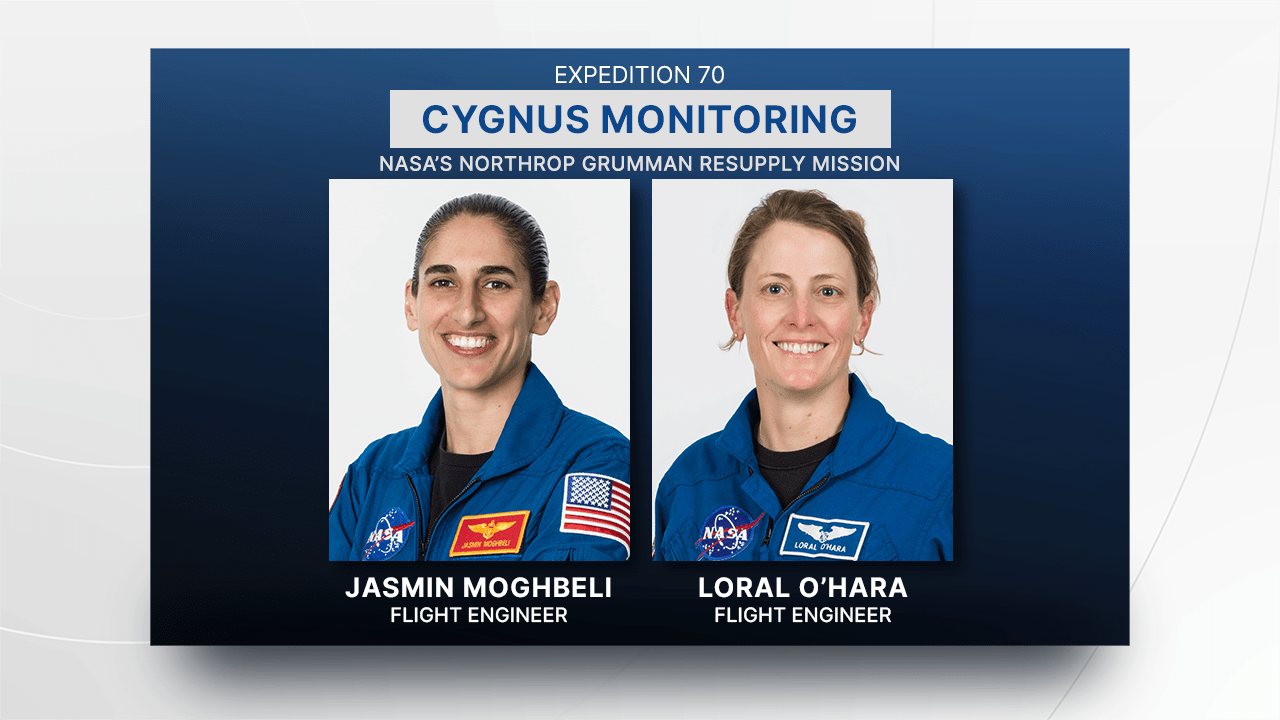

The Cygnus spacecraft will arrive at the orbiting laboratory at 3:35 a.m. Wednesday, Jan. 31, filled with supplies, hardware, and critical materials to directly support dozens of science and research investigations during Expeditions 70 and 71. NASA astronaut Jasmin Moghbeli will capture Cygnus using the station’s robotic arm, and NASA astronaut Loral O’Hara will act as backup.

After capture, the spacecraft will be installed on the Unity module’s Earth-facing port and will spend about six months connected to the orbiting laboratory before departing in May. Cygnus also provides the operational capability to reboost the station’s orbit.

After departure, the Kentucky Re-entry Probe Experiment-2 (KREPE-2), stowed inside Cygnus, will take measurements to demonstrate a thermal protection system for spacecraft and their contents during re-entry in Earth’s atmosphere, which can be difficult to replicate in ground simulations.

Live coverage of Cygnus’ arrival will begin at 2 a.m., Wednesday, Jan. 31.

Research Highlights

Scientific investigations traveling in the Cygnus spacecraft include tests of a 3D metal printer, semiconductor manufacturing, and thermal protection systems for re-entry to Earth’s atmosphere.

3D Printing in Space

An investigation from ESA (European Space Agency), Metal 3D Printer tests additive manufacturing or 3D printing of small metal parts in microgravity.

“This investigation provides us with an initial understanding of how such a printer behaves in space,” said Rob Postema of ESA. “A 3D printer can create many shapes, and we plan to print specimens, first to understand how printing in space may differ from printing on Earth and second to see what types of shapes we can print with this technology. In addition, this activity helps show how crew members can work safely and efficiently with printing metal parts in space.”

Results could improve understanding of the functionality, performance, and operations of metal 3D printing in space, as well as the quality, strength, and characteristics of the printed parts. Resupply presents a challenge for future long-duration human missions. Crew members could use 3D printing to create parts for maintenance of equipment on future long-duration spaceflight and on the Moon or Mars, reducing the need to pack spare parts or to predict every tool or object that might be needed, saving time and money at launch.

Advances in metal 3D printing technology also could benefit potential applications on Earth, including manufacturing engines for the automotive, aeronautical, and maritime industries and creating shelters after natural disasters.

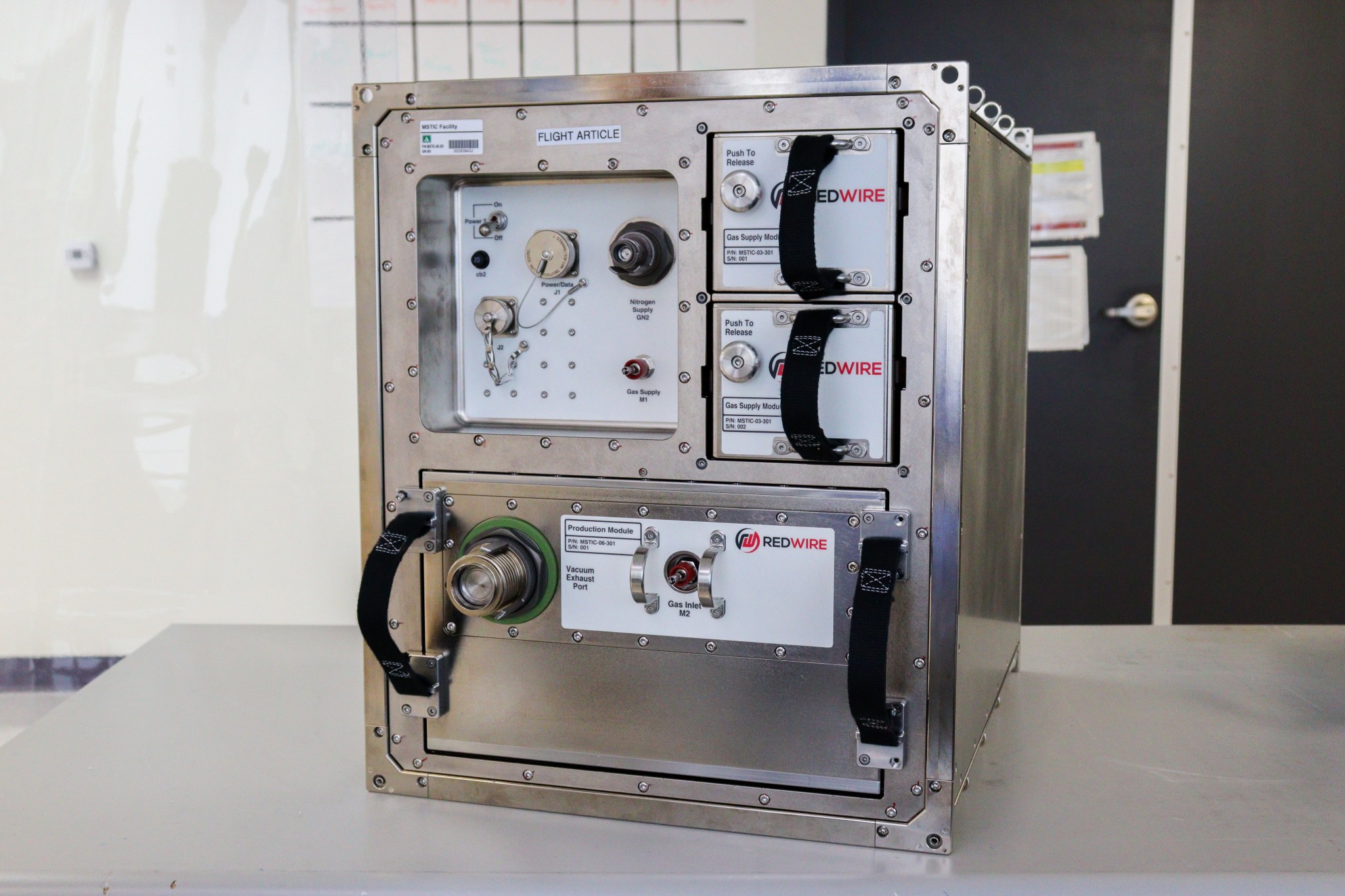

Semiconductor Manufacturing in Microgravity

Manufacturing of Semiconductors and Thin-Film Integrated Coatings (MSTIC) examines how microgravity affects thin films that have a wide range of uses.

This technology could enable autonomous manufacturing to replace the many machines and processes currently used to make a wide range of semiconductors, potentially leading to the development of more efficient and higher-performing electrical devices.

Manufacturing semiconductor devices in microgravity also may improve their quality and reduce the materials, equipment, and labor required. On future long-duration missions, this technology could provide the capability to produce components and devices in space, reducing the need for resupply missions from Earth. The technology also has applications for devices that harvest energy and provide power on Earth.

Modeling Atmospheric Re-Entry

Scientists who conduct research on the space station often return their experiments to Earth for additional analysis and study. But the conditions that spacecraft experience during atmospheric reentry, including extreme heat, can have unintended effects on their contents. Thermal protection systems used to shield spacecraft and their contents are based on numerical models that often lack validation from actual flight, which can lead to significant overestimates in the size of system needed and take up valuable space and mass. Kentucky Re-entry Probe Experiment-2 (KREPE-2), part of an effort to improve thermal protection system technology, uses three capsules outfitted with different heat shield materials and a variety of sensors to obtain data on actual reentry conditions.

“Building on the success of KREPE-1, we have improved the sensors to gather more measurements and improved the communication system to transmit more data,” said Alexandre Martin, principal investigator at the University of Kentucky. “We have the opportunity to test several heat shields provided by NASA that have never been tested before, and another manufactured entirely at the University of Kentucky, also a first.”

The capsules can be outfitted for other atmospheric re-entry experiments, supporting improvements in heat shielding for applications on Earth, such as protecting people and structures from wildfires.

Remote Robotic Surgery

Robotic Surgery Tech Demo tests the performance of a small robot that can be remotely controlled from Earth to perform surgical procedures. Researchers plan to compare procedures in microgravity and on Earth to evaluate the effects of microgravity and time delays between space and ground.

The robot uses two “hands” to grasp and cut rubber bands, which simulate surgical tissue and provide tension that is used to determine where and how to cut, according to Shane Farritor, chief technology officer at Virtual Incision Corp., developer of the investigation with the University of Nebraska.

Longer space missions increase the likelihood that crew members may need surgical procedures, whether simple stiches or an emergency appendectomy. Results from this investigation could support development of robotic systems to perform these procedures. In addition, the availability of a surgeon in rural areas of the country declined nearly a third between 2001 and 2019. Miniaturization and the ability to remotely control the robot help make surgery available anywhere and anytime on Earth.

NASA has sponsored research on miniature robots for more than 15 years. In 2006, remotely operated robots performed procedures in the underwater NASA’s Extreme Environment Mission Operations (NEEMO) 9 mission. In 2014, a miniature surgical robot performed simulated surgical tasks on the zero-g parabolic airplane.

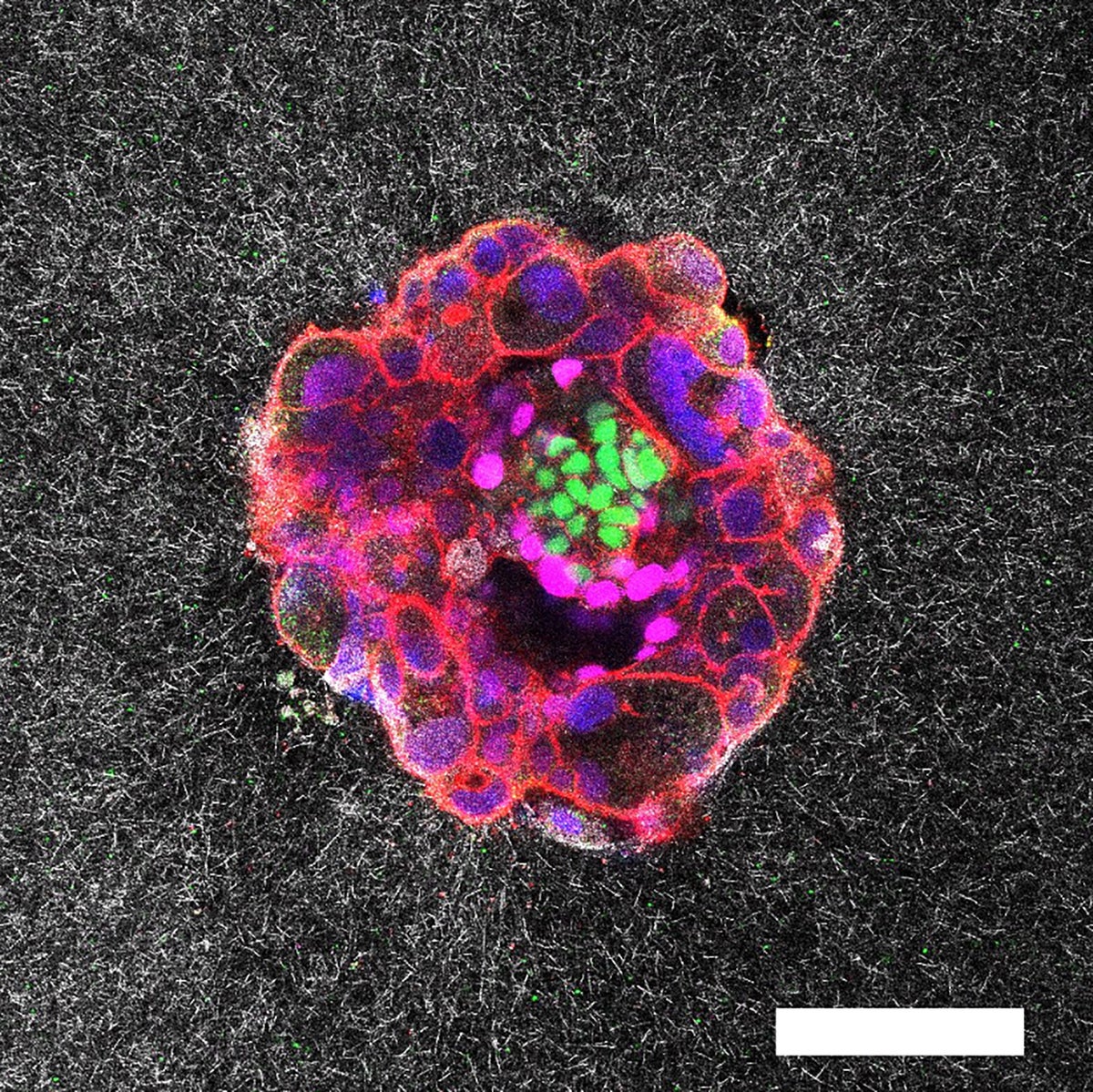

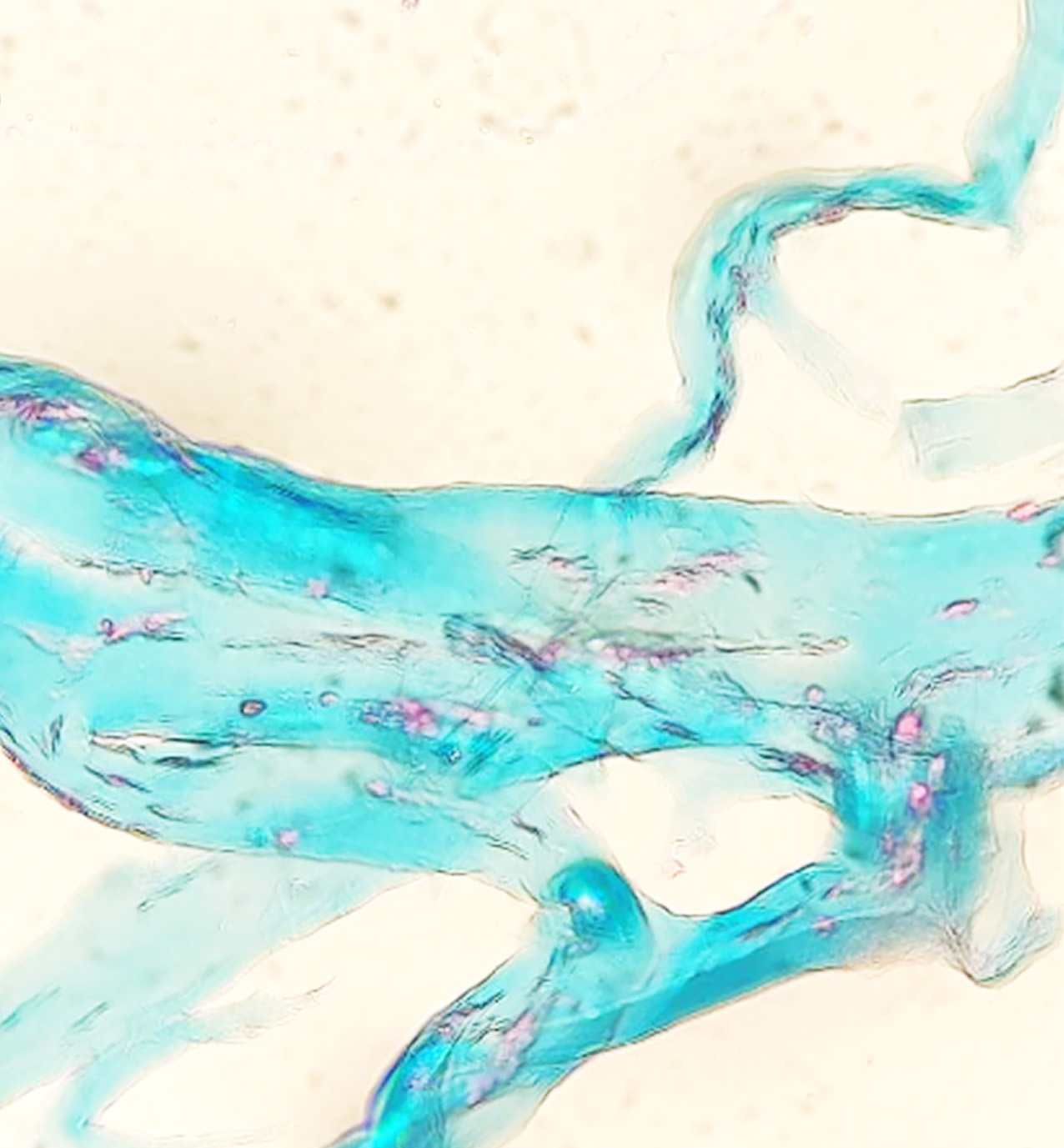

Growing Cartilage Tissue in Space

Compartment Cartilage Tissue Construct demonstrates two technologies, Janus Base Nano-Matrix and Janus Base Nanopiece. Nano-Matrix is an injectable material that provides a scaffold for formation of cartilage in microgravity, which can serve as a model for studying cartilage diseases. Nanopiece delivers an RNA (ribonucleic acid)-based therapy to combat diseases that cause cartilage degeneration.

Cartilage has a limited ability to self-repair and osteoarthritis is a leading cause of disability in older patients on Earth. Microgravity can trigger cartilage degeneration that mimics the progression of aging-related osteoarthritis but happens more quickly, so research in microgravity could lead to faster development of effective therapies. Results from this investigation could advance cartilage regeneration as a treatment for joint damage and diseases on Earth and contribute to development of ways to maintain cartilage health on future missions to the Moon and Mars.

Cargo Highlights

SpaceX’s Falcon 9 rocket will launch the Northrop Grumman Cygnus spacecraft to the International Space Station

Hardware

- Hydrogen Dome Assembly includes all hydrogen and oxygen electrolysis replacement components within the International Space Station’s Oxygen Generation Assembly. These items are contained in a sub-ambient dome maintained at near vacuum pressure, designed to contain an explosion or fire in the electrolysis cell stack during operation. The dome provides a second barrier to protect against cabin air internal leakage and external leakage into the rack environment, and is pressurized with nitrogen gas for launch. This will launch as an on-orbit spare.

- Ion Exchange Bed — The ion exchange bed replacement unit consists of a pair of tubes in series containing ion exchange resins, which remove organic acids from the catalytic reactor effluent, and microbial check valve resin, which injects iodine into the water as a biocide agent. This will launch as an on-orbit spare.

- Catalytic Reactor — The catalytic reactor replacement unit oxidizes volatile organics from the wastewater so they can be removed by the gas separator and ion exchange bed replacement units as part of the station’s water recycling system. This will launch as an on-orbit spare.

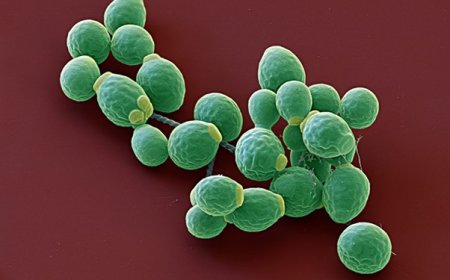

- Biocide Maintenance Canister — The Internal Thermal Control System Coolant Maintenance Assembly is designed to administer o-phthalaldehyde, a biocide used to purify the internal cooling loops in the Destiny laboratory, and the Harmony, Tranquility, Columbus, and Japanese Experiment Modules, to prevent the growth of microorganisms in the thermal control system. This unit will replace the current one installed in the laboratory.

- Cylinder Flywheel — The ARED (Advanced Resistive Exercise Device) cylinder-flywheel assemblies provide the resistive loads for astronaut anaerobic exercise. The cylinder flywheels impart inertial forces to simulate Earth’s gravity during exercise.

- International Space Station Roll Out Solar Array Modification Kit 7 – This upgrade kit consists of upper, mid, and lower struts (one each for left and right), a backbone, brackets, and support hardware for the new solar panels. This is the third in series of four modification kits needed to support the installation of the fourth set of upgraded solar arrays. The new arrays are designed to augment the station’s original solar arrays which have degraded over time. The replacement solar arrays are installed on top of existing arrays to provide a net increase in power with each array generating more than 20 kilowatts of power.

- Urine Processor Assembly Pressure Control and Pump Assembly — The assembly evacuates the urine distillation assembly at startup and periodically purges non-condensable gases and water vapor and pumps them to the separator plumbing assembly. The purge pump housing and pressure control and pump assembly manifolds are liquid cooled to promote steam condensation, thereby reducing the volume of the purge gas. All these systems make up the system used to covert urine to drinking water.

- Collection Packet and Adapter — Required for minimal, nominal water microbial sampling. In-flight water quality assessment is needed to assure that water of acceptable, defined quality will be available aboard the space station.

Watch and Engage

Live coverage of the launch from Cape Canaveral Space Force Station in Cape Canaveral, Florida, will air on NASA TV, NASA+ and the agency’s website. Live coverage will begin at 12:15 p.m.

Live coverage of Cygnus’ rendezvous and capture at the space station will begin at 3:35 a.m. Jan. 31. Read more about how to watch and engage.

What's Your Reaction?